CO2 System

CO2 is most likely the gaseous extinguishing agent that has the greatest number of installations worldwide. Its gather experience facilitates the engineering of many applications that have become standard, such as electrical generators, transformer stations.

Clean Agents

The FIKCO Fire Safety Solutions clean agent systems offer the highest efficiency for the most diverse hazard areas. In this clean agent system, Halocarbon gases work by total flooding, with discharges occurring within a few seconds to control the fire. All components which are used in this system come from the cylinder banks to the nozzles are developed to the highest quality assurance standards.

It works primarily through the immediate decrease in temperature of the protected room. The drastic removal of heat causes radical fire suppression.

Product Data:

- Rapid extinguishment.

- Discharge of less than 10 seconds.

- Wide range of pressures.

- Low noise discharges.

- It does not damage the ozone layer.

- Halon 1301 replacement

- High efficiency.

- Low extinguishing concentration.

- Non-toxic.

- Electrically non-conductive. Clean.

- Leaves no residue after discharge.

- Applicable in occupied areas.

Applications:

- Museums and art galleries

- Telecommunication systems

- Hospitals

- Petrochemical facilities

- Computer Rooms Archives and libraries

- Laboratories

- Electrical cabinets and substations

- Control Rooms

- Marine hazards

- Servers (DPCs)

- False floors and ceilings.

Inert Agents

FIKCO Fire Safety Solutions clean agent systems are made up of pure gases found in the atmosphere and are therefore completely ECO friendly. They work by completely flooding the room, reducing the oxygen content necessary for combustion, but at the same time ensuring adequate oxygen concentrations for use in occupied areas.

They can work at pressures up to 300 bar, providing savings in the installation and maintenance cost. We also have a 200 bar system, depending on the volume/concentration needs. Thanks to the use of calibrated restrictors which reduce the pressure, conventional schedule pipes can be used. This system is specifically designed for installations with longer distance pipe runs in big organizations like Hospitals, Pharmaceutical factories, etc.

Product Data:

- Zero ozone depletion potential (ODP) and the greenhouse effect.

- Allows for longer pipe runs.

- Very low refill cost.

- Easy to obtain anywhere in the world.

- Cost savings using selector valves.

- Suitable for occupied areas.

- Excellent post-discharge visibility

Applications:

- Electric and electronic applications.

- False floors and false ceilings.

- Archives, museums, and libraries.

- Computer rooms, control rooms.

- Electrical panels, telephone switchboard equipment.

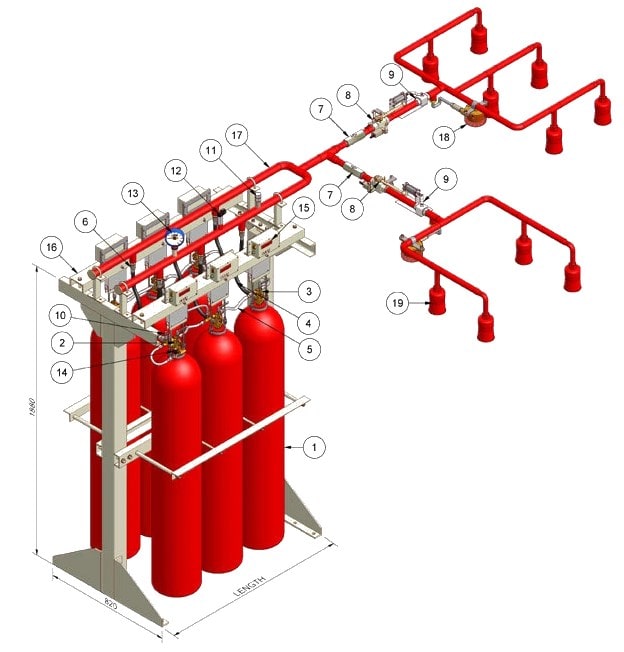

1 CO2 Cylinder

2 Master Valve

3 Slave Valve

4 Flexible Discharge Hose

5 Flexible Inter Connecting Hose

6 Non-Return Valve

7 Inline Check Valve

8 Lock Out Valve

9 Directional Valve

10 Bleeder Valve

11 Safety Release Valve

12 Pressure Switch

13 Pressure Gauge

14 Solenoid Valve

15 Digital Weight Loss Indicator

16 Cylinder Mounting Frame

17 Manifold

18 Pressure Operated Siren

19 CO2 Discharge Nozzle

20 Weight Loss Indicator